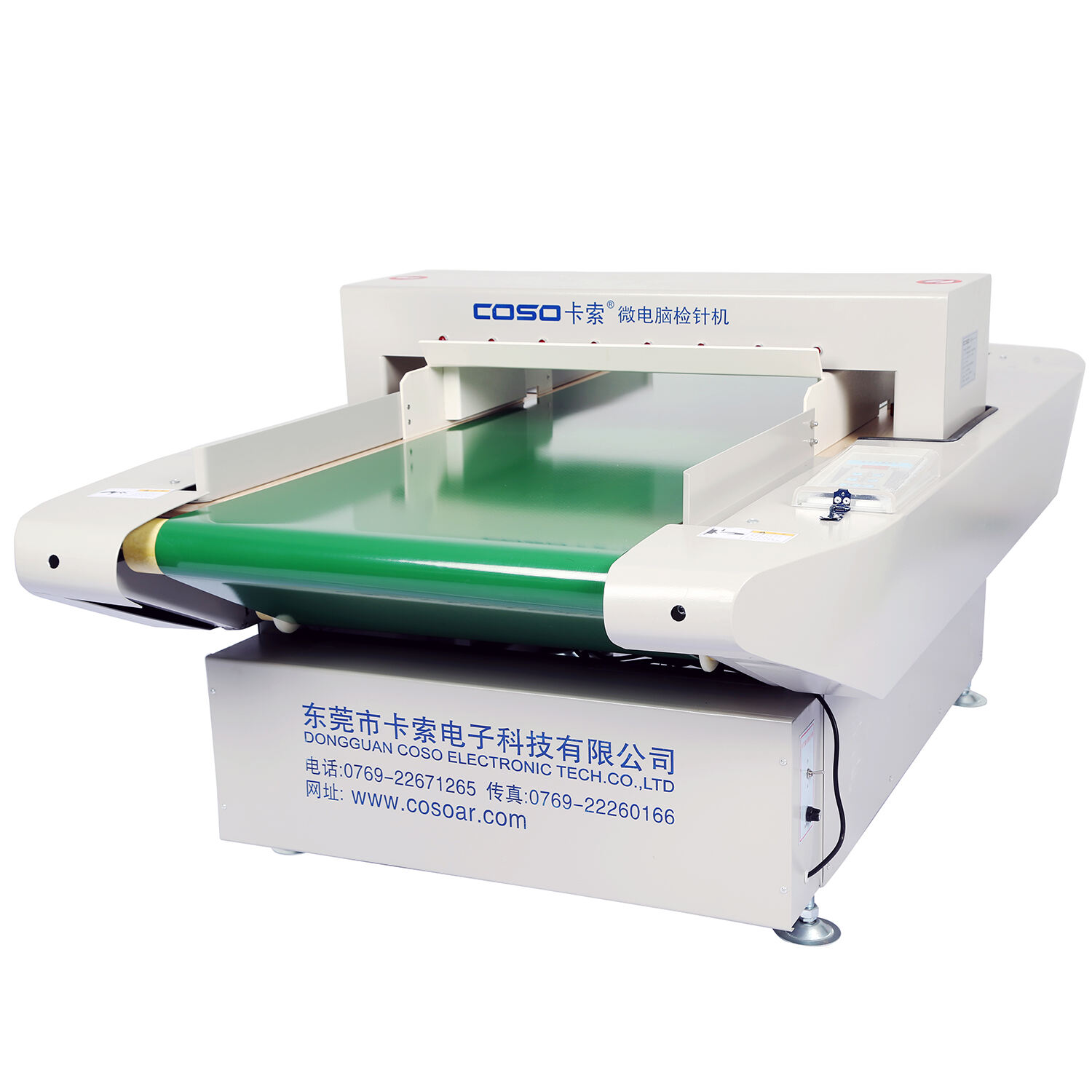

Detector de Metales para la Industria de Reciclaje de Plástico

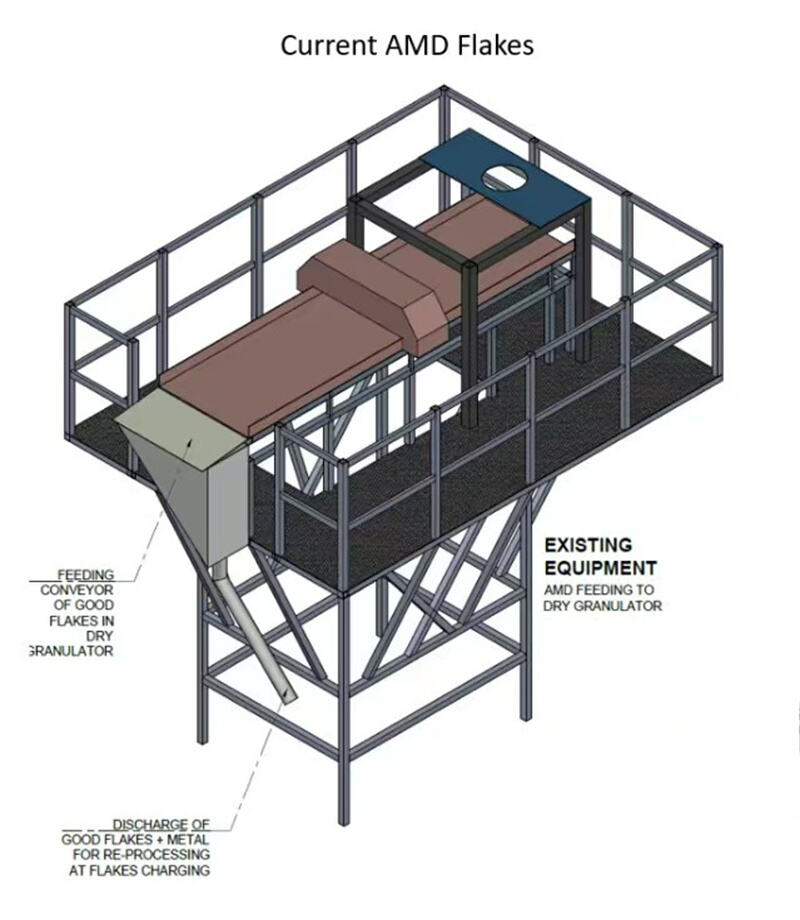

Una fábrica especializada en la reciclaje de plástico se acercó a nosotros con una solicitud para instalar un detector de metales en su línea de limpieza de botellas. El producto a detectar son virutas de PET en forma bulk, y el detector de metales necesitaba instalarse en un piso elevado en lugar de en el suelo. Para facilitar la comprensión, sus ingenieros proporcionaron un diagrama detallado del modelo y especificaron requisitos claros, incluida la necesidad de un mecanismo de rechazo por solapas para eliminar las virutas que contengan impurezas metálicas.

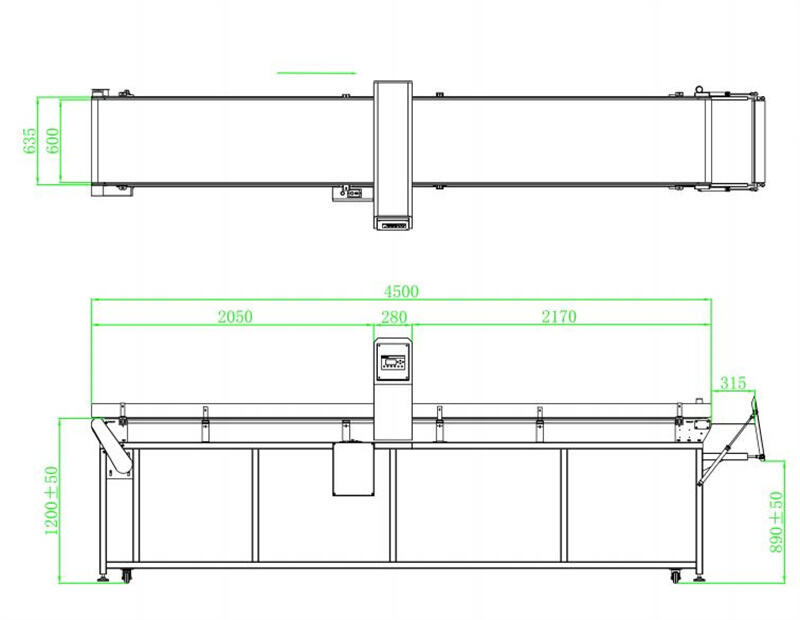

Uno de los principales desafíos en este proyecto fue la exigencia del cliente de una longitud de la cinta transportadora de 4,5 m. Por lo general, nuestros detectores de metales vienen con longitudes de cinta estándar de 1,5 m, 1,6 m, 1,8 m y 2 m, que normalmente satisfacen las necesidades de la mayoría de los clientes. Sin embargo, este caso era particularmente único debido a las restricciones de la instalación elevada, dejando sin espacio para ajustes en la longitud.

Nuestro equipo técnico llevó a cabo un rediseño de la estructura de la máquina.

Finalmente, la máquina fue entregada a nuestro cliente y funciona correctamente en el lugar.