Rilevatore Metallico per Tutto il Pacco di Caramelle

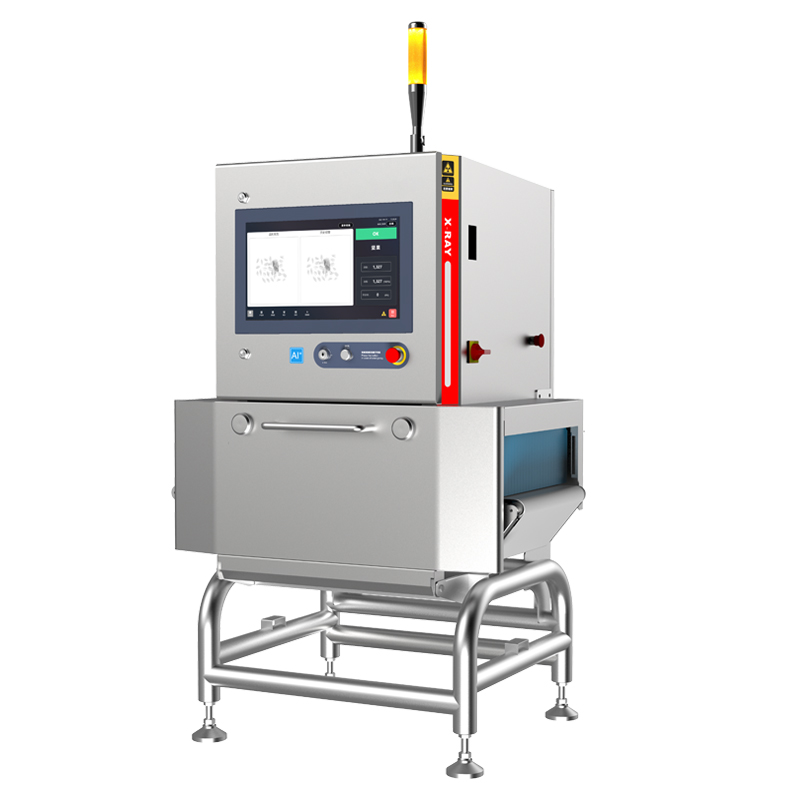

Un produttore di caramelle si è rivolto a noi con la richiesta di integrare un rilevatore di metalli nella loro linea di produzione semi-automatica. Secondo le specifiche fornite, il rilevatore di metalli sarebbe stato installato dopo la macchina per l'imballaggio. Nel loro processo attuale, gli operai mettono le caramelle nelle scatole, che vengono poi sigillate da una macchina di sigillatura automatica. Le scatole sigillate vengono trasportate tramite rulli motorizzati alla cinghia trasportatrice del rilevatore di metalli. Per garantire una transizione fluida, abbiamo progettato la cinghia trasportatrice del rilevatore di metalli allo stesso livello dei precedenti rulli, minimizzando qualsiasi interruzione nel flusso di lavoro.

Uno dei principali vantaggi del nostro rilevatore di metalli è la sua galleria di rilevamento personalizzabile, che consente di gestire sia materiali a granello che intere scatole di caramelle. Questa flessibilità garantisce che la macchina possa adattarsi a varie esigenze di produzione.

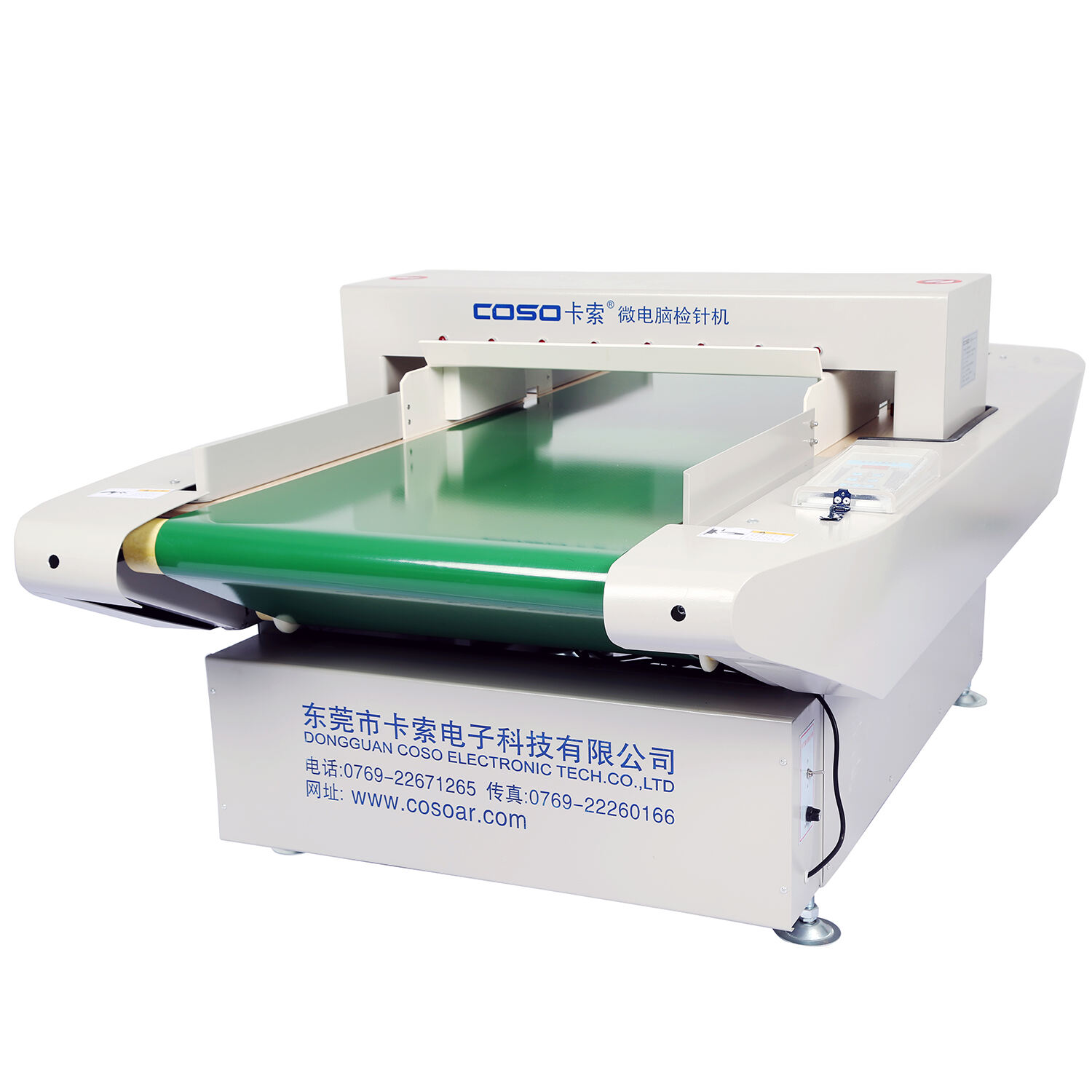

A proposito, il tipo di confezione dei dolciumi gioca un ruolo critico nella scelta del metal detector appropriato. Se i dolciumi sono avvolti in carta d'alluminio, il nostro rilevatore di metalli standard - in grado di rilevare ferro, acciaio inossidabile e rame - non può essere utilizzato. Invece, offriamo un rilevatore di metalli specializzato per la carta d'alluminio, che è specificamente progettato per prodotti con confezioni in carta d'alluminio. Questo modello riesce a rilevare solo il ferro, poiché la carta d'alluminio interferisce con il rilevamento di altri metalli.

Dongguan Coso Electronic Tech Co., Ltd