Hệ thống Kiểm tra Tia X cho Quả xoài

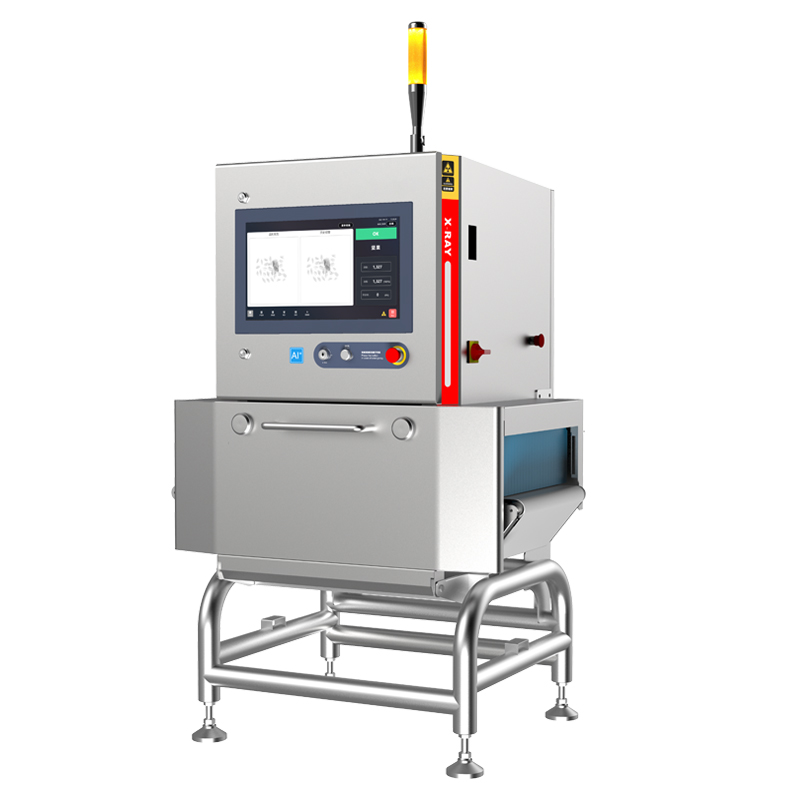

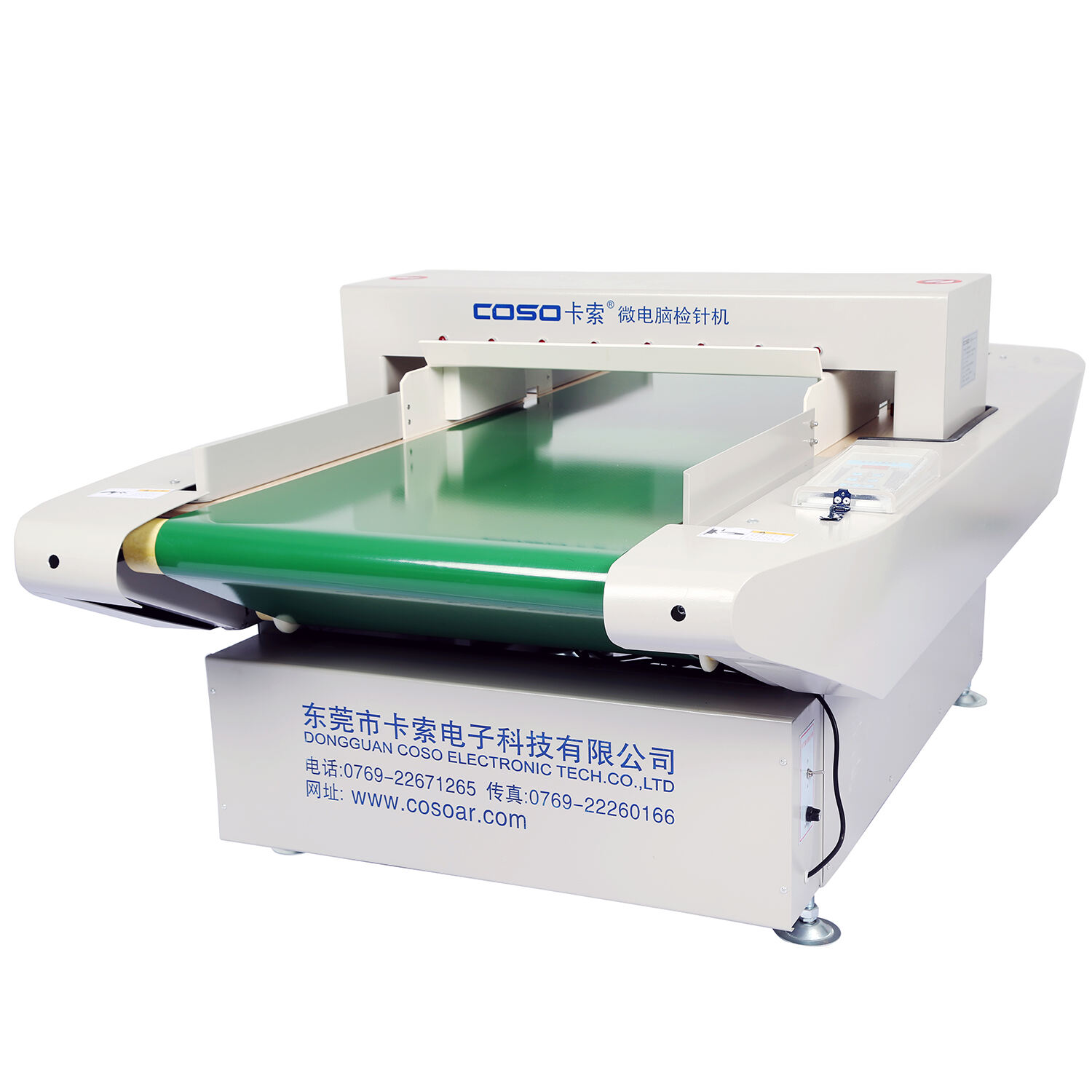

Máy chụp X-quang có phạm vi ứng dụng rộng rãi, bao gồm sử dụng y tế trong bệnh viện, kiểm tra an ninh tại sân bay hoặc nhà ga, và sử dụng công nghiệp trong nhà máy. Trong môi trường công nghiệp, hệ thống kiểm tra X-quang của chúng tôi chủ yếu được sử dụng như thiết bị phát hiện với hai mục đích chính. Thứ nhất, chúng phát hiện tạp chất trong sản phẩm, chẳng hạn như kim loại, đá, và xương cá. Khác với máy dò kim loại truyền thống, vốn chỉ có thể nhận diện các tạp chất kim loại và bị giới hạn khi phát hiện sắt trong bao bì bằng giấy nhôm, hệ thống kiểm tra X-quang không bị ràng buộc bởi vật liệu bao bì. Chúng có khả năng phát hiện một phạm vi rộng hơn các tạp chất, làm cho chúng linh hoạt hơn. Thứ hai, hệ thống kiểm tra X-quang được sử dụng để kiểm tra các khuyết tật của sản phẩm, chẳng hạn như lõm trên lon hoặc hư hỏng bên trong trái cây.

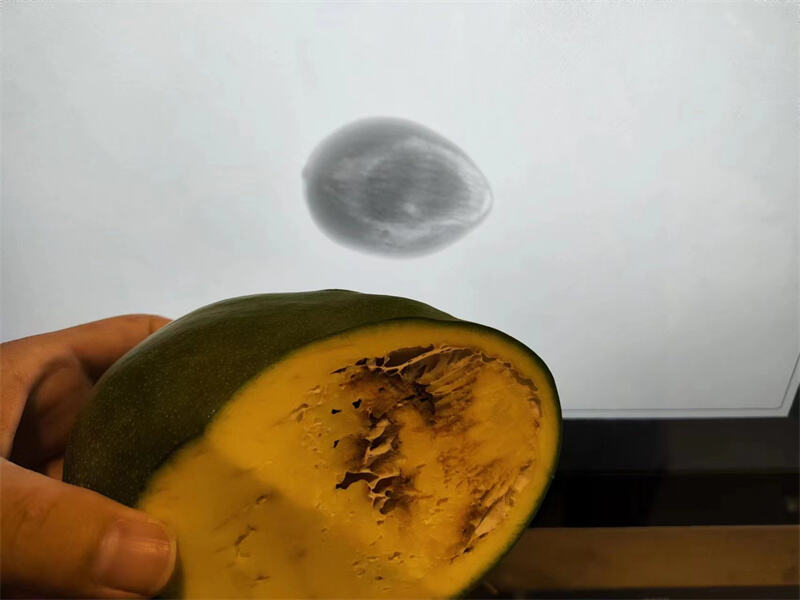

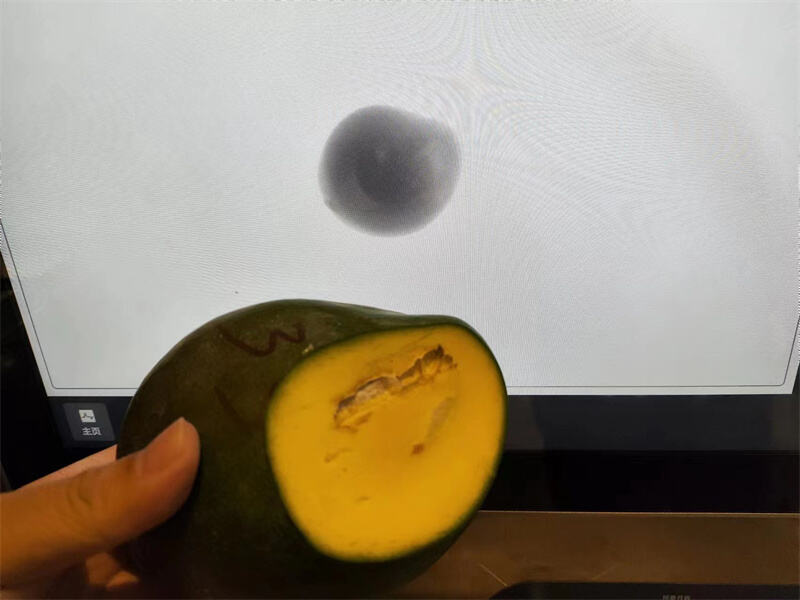

Hôm nay, chúng ta sẽ tập trung vào việc áp dụng hệ thống kiểm tra X-quang trong việc phát hiện xoài bị thối.

Hệ thống kiểm tra tia X hoạt động dựa trên nguyên lý chụp ảnh tia X, trong đó sự khác biệt về mật độ của các vật thể dẫn đến sự thay đổi trong hình ảnh. Khi một quả xoài bắt đầu thối bên trong, sự thay đổi về mật độ sẽ được phản ánh trong hình ảnh tia X, như được hiển thị trong minh họa dưới đây.

Hệ thống kiểm tra tia X của chúng tôi được trang bị thuật toán AI có khả năng tự học. Bằng cách cung cấp cho máy các mẫu xoài đạt tiêu chuẩn và các loại xoài hư khác nhau để huấn luyện, nó có thể học cách tự động nhận diện những quả xoài lỗi. Khi phát hiện ra trái cây hư, máy sẽ kích hoạt báo động bằng âm thanh và hình ảnh. Nó có thể dừng băng chuyền hoặc tự động loại bỏ quả xoài lỗi khỏi dây chuyền, tùy theo yêu cầu mà được tùy chỉnh. Nếu máy cần được tích hợp vào một dây chuyền sản xuất sẵn có, chúng tôi có thể cung cấp giải pháp tùy chỉnh.

Dongguan Coso Electronic Tech Co., Ltd