식품 가방 체중 검사기

한 음식 가방 제조업체가 포장 기계 이후에 설치할 체중 검사기를 요청하며 우리에게 접근했습니다. 목표는 제품의 무게가 요구되는 표준을 충족하는지 확인하고, 저체중 또는 과체중인 패키지를 식별하는 것이었습니다. 일반적으로 생산 라인에 체중 측정기를 통합하면 수작업 피딩에 비해 더 나은 결과를 얻을 수 있습니다. 이는 동적 측정에서 제품의 컨베이어 벨트 위 위치와 그 무게의 균일성이 정확도에 크게 영향을 미칠 수 있기 때문입니다. 생산 라인에서는 각 제품의 위치가 거의 동일하지만, 수작업 피딩은 변동성을 초래할 수 있습니다.

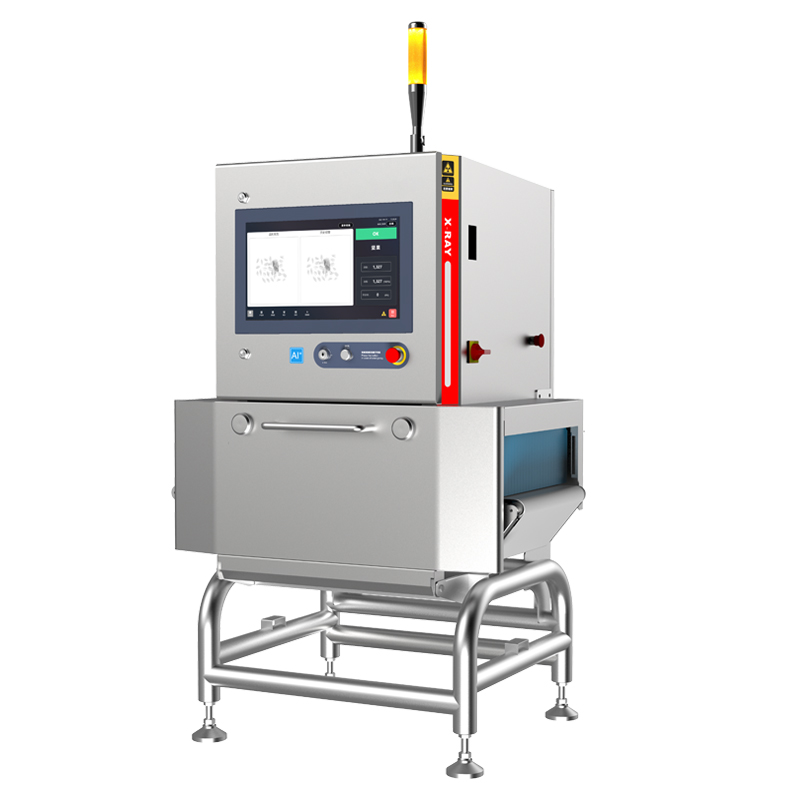

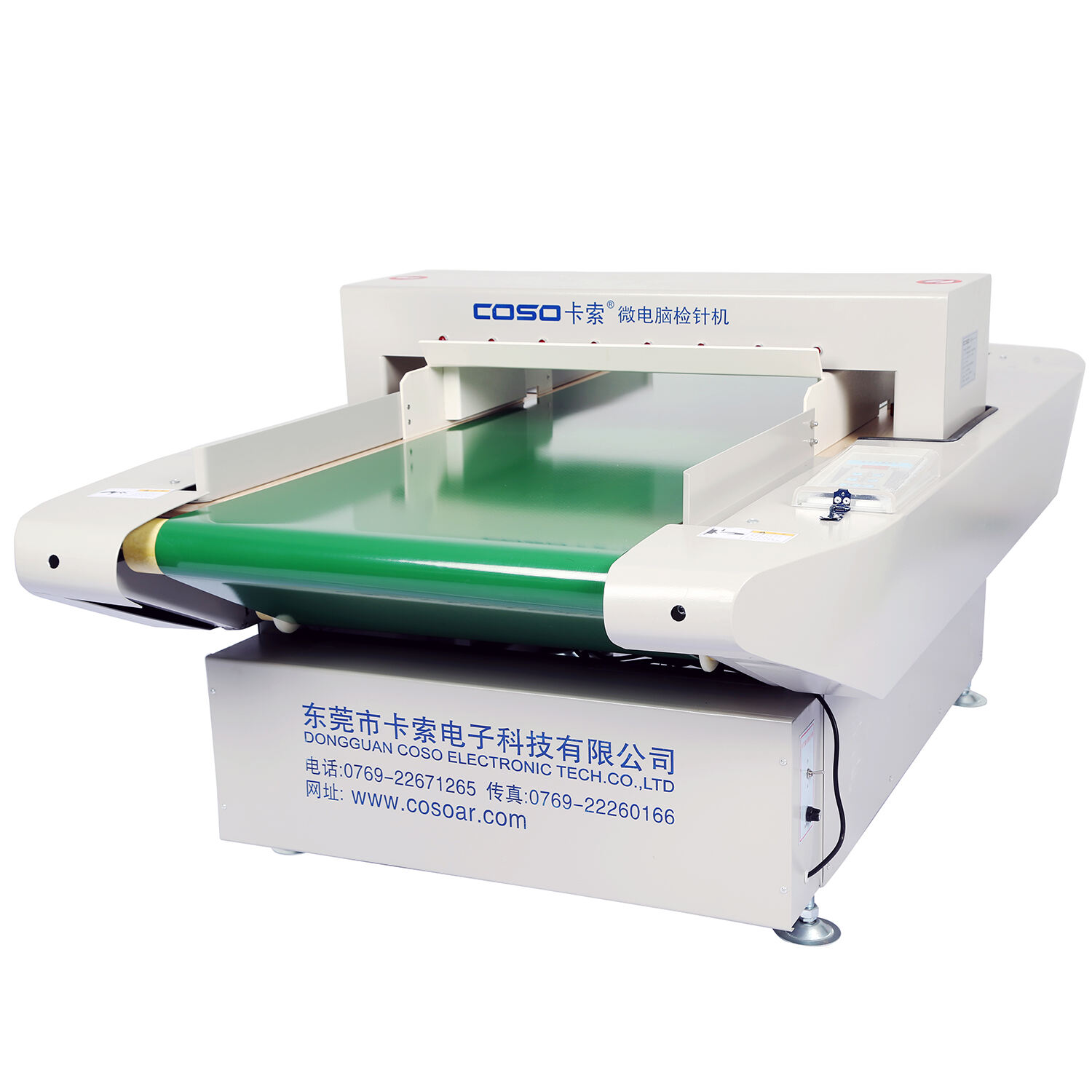

우리는 다양한 제품 크기에 맞춰 여러 가지 체중 검사기 사이즈를 제공합니다. 우리의 체중 측정기는 일반적으로 피드 섹션, 측정 섹션, 그리고 반품 섹션으로 구성됩니다. 제품의 길이와 너비는 일반적으로 측정 섹션의 크기를 초과해서는 안 됩니다.

위의 기계는 푸셔식 불량품 제거 방식을 채택하고 있습니다. 만약 제품이 더 얇다면 벨트 싱킹 방식의 불량품 제거 시스템이 더 적합할 것입니다. 이 시스템은 종이 시트나 타월과 같은 얇은 물체에 이상적입니다. 이러한 설계는 우리 회사의 강점 중 하나입니다.

Dongguan Coso Electronic Tech Co., Ltd