Check Weigher for Food Bag

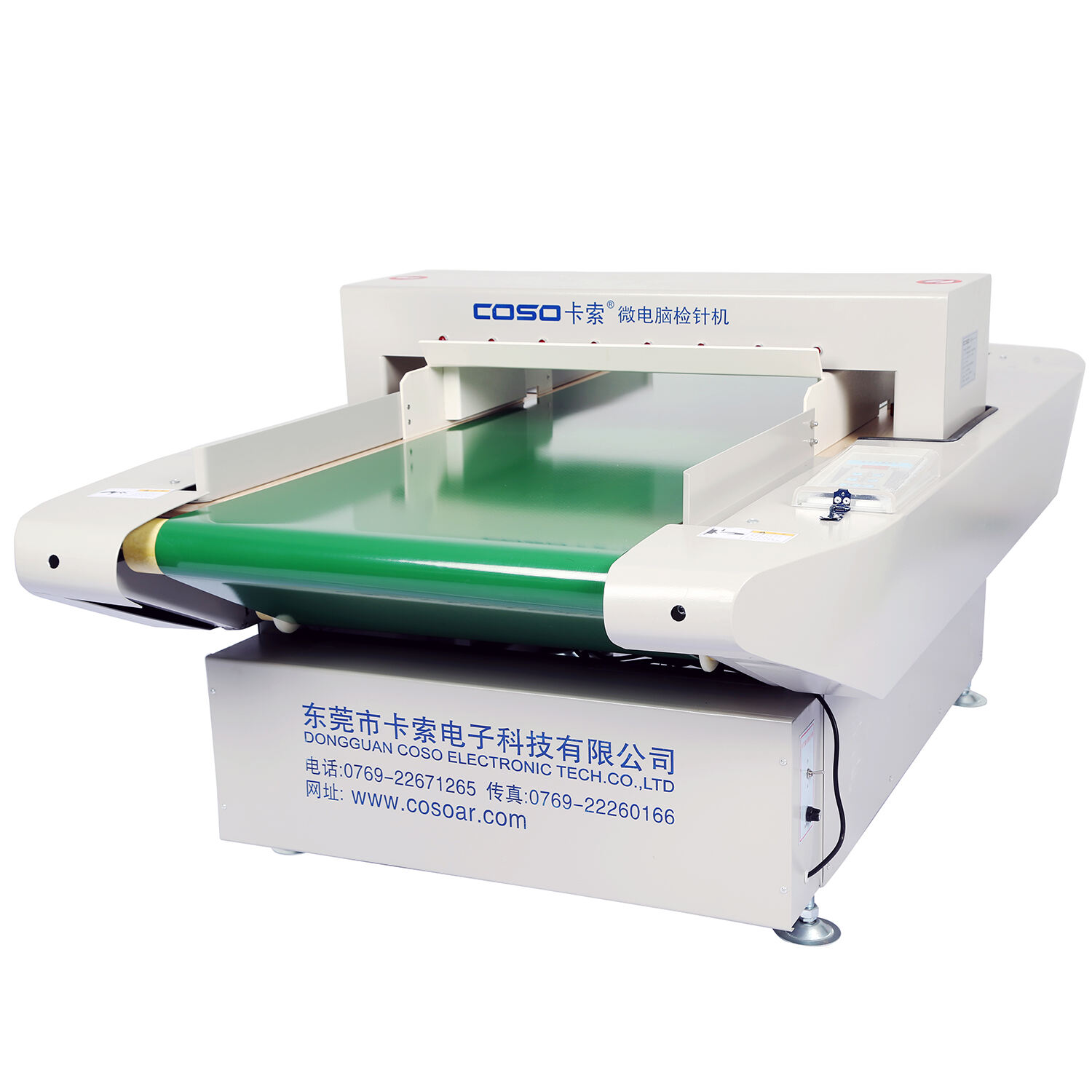

A food bag manufacturer approached us with a request for a check weigher to be installed after their packaging machine. The goal was to detect whether the product weight met the required standards, thereby identifying underweight or overweight packages. Generally, integrating a weighing machine into a production line yields better results compared to manual feeding. This is because, in dynamic weighing, factors such as the position of the product on the conveyor belt and the uniformity of its weight can significantly affect accuracy. In a production line, the position of each product is nearly identical, whereas manual feeding can introduce variability.

We offer multiple check weigher sizes to accommodate different product dimensions. Our weighing machines typically consist of three sections: a feed section, a weighing section, and a rejection section. The length and width of the product should generally not exceed the size of the weighing section.

The machine shown above adopts the pusher rejection, if the product were even thinner, a belt-sinking rejection system would be more appropriate. This system is ideal for thin items such paper sheets or towel. This design is one of our advantages.

Dongguan Coso Electronic Tech Co., Ltd