Product Description

Inquiry

Related Products

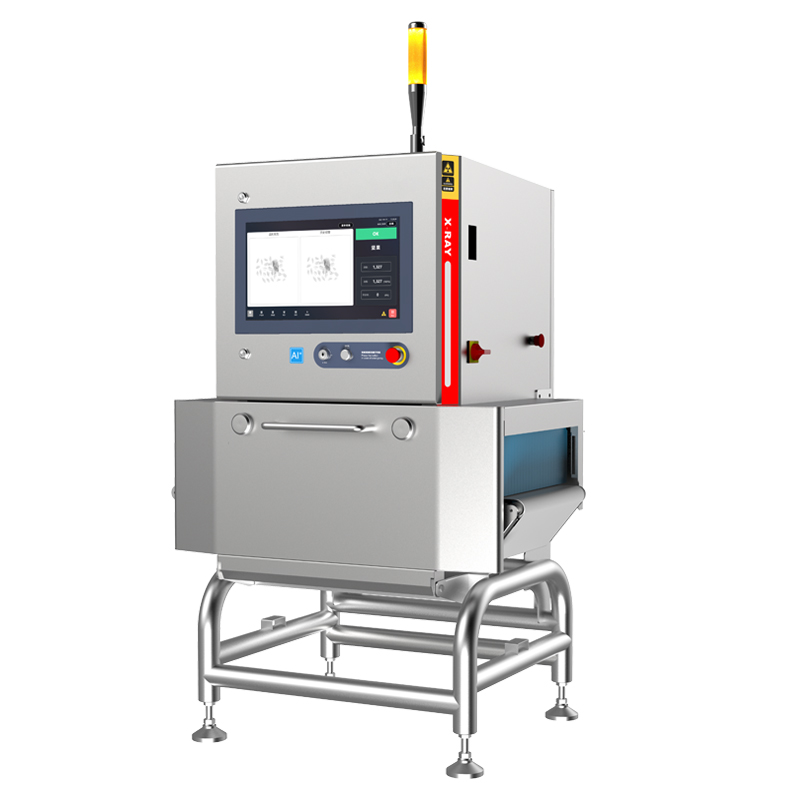

The X-ray intelligent defect detection system utilizes leading artificial intelligence technology, AI-XSP imaging algorithm, achieving high-precision and highly adaptive detection of foreign objects and defects, providing effective technical support for improving production quality and efficiency in enterprises.

1. AI based intelligent defect recognition algorithm; Equipped with software self-learning function and excellent detection accuracy

2. It can support small foreign objects such as metal, glass, stones, bones, etc., with strong applicability and high detection accuracy

3. Supports multiple defect detection methods such as cracking, missing/missing corners, and overlapping, with high accuracy

4. Open calibration tools, expand detection applications, and easily have your own algorithms

5. Stable conveying structure, flexible design, and easy integration with existing production lines;

6. Multiple models are available, supporting packaging product, bulk material testing, etc; Can add with various types of rejection types.

Features

1. Good intelligent recognition effect

The X-ray intelligent defect detection system is widely used in the detection of foreign objects in packaged seed foods, sugary foods, frozen foods, snack foods, dairy products, baked goods, fruit and vegetable products, and aquatic products, efficiently identifying malignant impurities such as metals, glass, and stones contained in food and medicine. The ultra-high resolution sensor is equipped with AI modeling method, which has strong adaptive ability and effectively eliminates background interference, making extremely small foreign objects nowhere to hide. The device can also achieve parallel detection of product defects

2. Scalable detection types

The X-ray intelligent defect detection system not only efficiently and accurately removes common metal foreign objects, but also supports AI open platforms, open calibration tools, and is effective for enterprise production of goods. Train algorithm models, expand detection types, and then achieve intelligent detection of specific impurities, eliminate problematic products, and prevent them from entering the market.

3. Equipment parameters are free of debugging

The X-ray intelligent defect detection system has excellent quality, which is not only easy to install and durable, but also user-friendly in software operation and guided configuration. It is easy to operate and can be used in minutes, More support for parameter adaptation, suitable for various complex production environments.

Specification: XS-4016

| Item | Parameter | |

| Structure | Tunnel width | 400mm |

| Tunnel height | 160mm | |

| Whole size of machine | 2009(H)*1094(L)*902(W), 380Kg | |

| Frame material | SUS304 | |

| Conveying | Belt material | Food grade PU |

| Belt width | 440mm | |

| Height from belt to floor | 800±50mm | |

| Conveying speed | 10~60m/min | |

| Maximum load | 10kg | |

| X Ray | X-ray tube voltage | 40~80kv |

| X device tube current | 200-5000μA | |

| X-ray power | 210W | |

| Sensitivity | Stainless steel ball (Φ) | 0.3mm |

| Stainless steel wires (Φ) | 0.2*2mm | |

| Glass ball(Φ) | 1.0mm | |

| Ceramic ball (Φ) | 1.0mm | |

| Algorithm support | Foreign object/defect detection | |

| Configuration | IP Level | Conveying:IP66 |

| Other:IP54 | ||

| Alarm mode | Sound and Light | |

| Screen | 21.5-inch touch screen, resolution 1920 * 1080 | |

| Cooling method | Industrial air conditioning | |

| Protection method | 4 layers of protective curtains at entrance and exit | |

| Radiation safety | ≤1μSv/h | |

| Power supply | AC220V,50/60HZ | |

| Working temperature | -10~40℃ | |

| Interface | Ethernet, USB; Support MES docking | |