ထုတ်ကုန်ဖော်ပြချက်

မေးမြန်းချက်

ပတ်သက်သော ပণုံများ

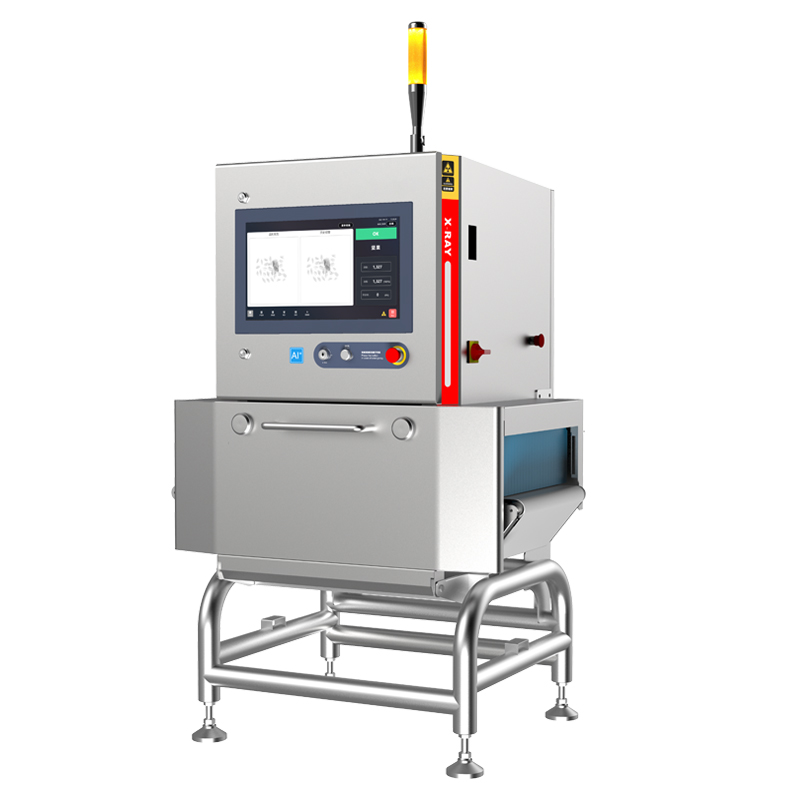

X-ရောင် အသွေးပစ္စည်း ဆုံးဖြတ်မှု စနစ်သည် အကောင်းဆုံး အလှူရှိ ဘာသာရပ် စမ်းသပ်မှု နည်းပညာကို အသုံးပြု၍ AI-XSP ထုတ်ရှားမှု ချဉ်းကပ်မှုကို ရှိရှိရှိုးရှုံး ဆုံးဖြတ်မှု၊ အသွေးပစ္စည်း ဆုံးဖြတ်မှု အကျိုးသော အကျိုးအမြတ်များကို ရရှိနိုင်စေပြီး လုပ်ငန်းအားလုံး၏ ပณ္ဏုပိုင်း အရွယ်အစားနှင့် ကုမ္ပဏီ၏ ထုတ်လုပ်မှုအရွယ်အစားကို တိုးတက်စေရန် ကူညီပေးသည်။

1. ပျော်ပြားသော ပစ္စည်းများ၊ ကာန်များနှင့် ဘক်စီများကို ထိုးထားသော ထုတ်လုပ်မှုများအတွက် အသုံးပြုနိုင်သည်။ အမြဲတမ်း အလှောင်းနှစ်ခုဖြင့် လျင်မြန်စွာ ပေါင်းစပ်ထားသည်။ အားလုံးကို အလွန် အသွေးပစ္စည်းများ၊ အိမ်ကျောက်၊ ကြေး၊ အိမ်ကျောက်သော ပျော်ပြားမှုများကို ထောက်ခံပေးသည်။

2. AI အလှူရှိ အသွေးပစ္စည်း အက်လ်ဂိုရီသမ်များအား အခြေခံပြီး ဆုံးဖြတ်ချက်များကို မပိုဒ်ပိုဒ်များ၊ မကာကွယ်များ၊ မှန်ကန်သော မျက်နှာပြင်များကို ဆုံးဖြတ်နိုင်သည်။

3. ရေပြားအဆင့် (ဖျော်ထည့်မှုအမြင့်)၊ ပျော်ပြားမှု၊ ဆေးချိုးမှု၊ အသွေးပစ္စည်းများ၏ အမှားများကို အလွန်တိုင်းတာမှုဖြင့် ဆုံးဖြတ်နိုင်သည်။

4. ဖွင့်ထားသော ကိုင်တွယ်မှုများ၊ ဆုံးဖြတ်မှုအသုံးပြုမှုများကို ဖွင့်ချင်းပေးပြီး အသုံးပြုသူများအား သူတို့၏ အလှူရှိ အက်လ်ဂိုရီသမ်များကို လွယ်ကူစွာ ရရှိနိုင်စေသည်။

၅. ပို့ဆောင်ရေးဖွဲ့စည်းမှူးသည် လျှော့ချထားသည်၊ ဒီဇိုင်းမှာ လွယ်ကူသည်၊ နှင့် အသုံးပြုသူ၏ လိုအပ်ချက်များအရ လမ်းကြောင်းအရွယ်အစားကို အတိုင်းအတာပြုလုပ်နိုင်ပြီး ရှိသော ထုတ်လုပ်မှုလုပ်ငန်းများတွင် အသုံးပြုရန် လွယ်ကူသည်။

X-ရေး အကြံပြုသော ပြင်ပစ္စာများကို ရွေးချယ်ရေး စနစ်သည် ထောင့်ထိုးထားသော ဘောတ်၊ ကိုင်တာန်း၊ နှင့် ပုံမှန်အားဖြင့် ပို့ဆောင်သည့် ထုတ်ကုန်များတွင် ပြင်ပစ္စာများကို ရွေးချယ်ရန်အတွက် ကျယ်ပြန့်သုံးသည်။ အစားအစာနှင့် ဆေးဝါးတွင် ပါဝင်သော မီတာများ၊ ကျောက်များ၊ နှင့် ကျောက်များ အတွင်းရှိ ဆိုးရွားသော ပြင်ပစ္စာများကို ကြိုးစားစွာ ရွေးချယ်နိုင်ပါသည်။ အိုင်အီ မှတ်တမ်းပြုခြင်းနည်းလမ်းဖြင့် ပြင်ဆင်ထားသော အားလုံးကိုင်းရေး ဆိုင်ရာ အားဖြင့် ပြင်ပြီး နောက်ခံ ပြင်ပစ္စာများကို ကာကွယ်ပေးနိုင်ပြီး အလွန်လျော့ချသော ပြင်ပစ္စာများကို မျှော်လင့်မှုမရှိပါ။ ထုတ်ကုန်၏ အမျိုးအစားများကို အတူတူ စစ်ဆေးနိုင်ပြီး တစ်ခုလုပ်ငန်းတွင် များသော အသုံးများ ပြောင်းလဲနိုင်ပြီး ကျွန်းစားသော ရွေးချယ်မှုကို ပေးနိုင်သည်။

X-ရောင် အကြံပြုချက်ဖြင့် ပစ္စည်းများကို တွေ့ရှိရန် စနစ်သည် မူလတန်း ဒွိအလင်းရထားများဖြင့် ဆောင်ရွက်ထားပြီး၊ အလားတူ အသေးစိတ်ကို လဲလှယ်ရန် AI တံဆိပ်ကို အသုံးပြုထားသည်။ စစ်ဆေးခြင်းအတွက် ဒေသများကို ခွဲခြားသော်လည်း မပါဝင်ပေ၊ အမှန်တကယ် များသော အမှောင်ကို ရှာဖွေရန် ဖြစ်သည်။

X-ရောင် အကြံပြုချက်ဖြင့် ပစ္စည်းများကို တွေ့ရှိရန် စနစ်သည် အရည်အချင်းအရောင်းပြီး၊ ဖောက်ထားသော အခြေအနေများကို လွယ်ကူစွာ အသုံးပြုနိုင်ပြီး အသုံးပြုသူများအတွက် လွယ်ကူစွာ အလုပ်လုပ်နိုင်သည်။ အသုံးပြုသူများအတွက် အကြံပြုချက်များကို အကြံပြုပေးနိုင်ပြီး အလွယ်တကူ အသုံးပြုနိုင်သည်။ အပြင်အဆင်များကို အကောင်အထည်ဖော်နိုင်ပြီး ရာဇဝတ်များအတွက် အကောင်အထည်ဖော်နိုင်သည်။

Specification: XS-1625D

| အပိုင်း | ပါရမီတာ | |

| ဖွဲ့စည်းမှု | လမ်းကြောင်းအကျယ် | ၁၆၀မီလီမီတာ |

| လမ်းကြောင်းအမြင့် | 250mm | |

| စက်ရုံ၏ အရွယ်အစား | 2150(H)*4200(L)*1500(W), 1000Kg | |

| ဘောင်ခင်းပစ္စည်း | SUS304 | |

| ပို့ဆောင်ခြင်း | ဘယ်လောက်ပစ္စည်း | အစားအစာ PU |

| ဘောင်အကျယ် | 150mm | |

| ပေါင်းမှ အိမ်သားထိပ်သို့ အရتفاع | 800±50mm | |

| လှိုင်းလုပ်ငန်းအမြန် | 30~60m/မိနစ် | |

| အများဆုံး ထိုးဝိုင်း | 15kg | |

| X ရောင် | X-ray ကြီးကျယ်ခွဲတိုက်ဖိုင်းဒေါင်းထုတ်လုပ်မှု | 60~120kv |

| X ကိရိယာ ကြီးကျယ်ခွဲတိုက်ဖိုင်းဒေါင်းလျှော့ချမှု | 200-7500μA | |

| X-ရောင်အင်အား | 480W | |

| လွန်ခွဲမှု | Stainless steel ball (Φ) | ၅ မီလီမီတာ |

| Stainless steel wires (Φ) | 0.3*2mm | |

| အိမ်ကျောင်း (Φ) | 1.5mm | |

| စီရာမစ်ဘော်လ် (Φ) | 1.5mm | |

| ယာဉ်ချုပ်တွေ့နည်း ထောက်ခံ | ပြင်ပပစ္စည်း / ဆိုးမှု ရှာဖွေရေး | |

| ပုံပြင် | IP အဆင့် | သယ်ယူခြင်း: IP66 |

| အခြား: IP54 | ||

| အန္တရာယ်အန္တရာယ်အန္တရာယ် | သံနှင့် အလင်း | |

| မျက်နှာပြင် | 21.5-အင်္ဂါ ထိုးမီးနှုန်း မျဉ်းချင်း၊ ရဲရှင်း 1920 * 1080 | |

| အအေးပေးနည်း | မီးကောင်းလုပ်ငန်း လေထိုင်ခြင်း | |

| ထားရှိမှု နည်းလမ်း | ရှေ့ဒီ | |

| အလျင်အသီးခြံစီးရှုံးမှု သိမ်းချုပ်ရေး | ≤1μSv/h | |

| အင်တင်စီးမှု | AC220V, 50/60HZ | |

| အလုပ်လုပ်သော အပူချိန် | -10~40℃ | |