Ürün Açıklaması

Sorgu

İlgili Ürünler

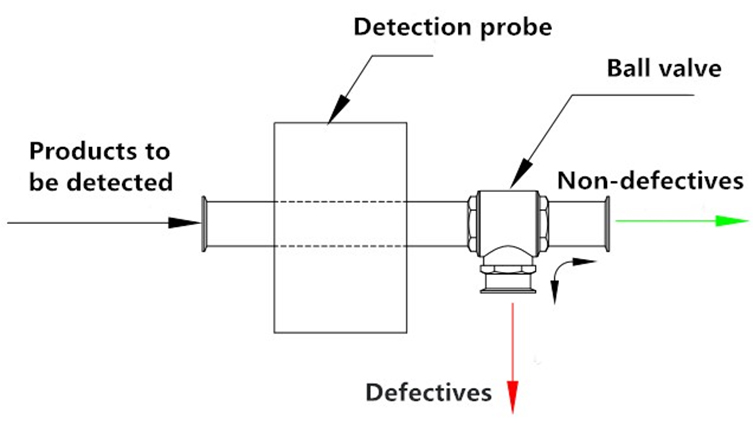

şEMA

EC2005E sıvı metal ayırıcı, metal tespitini tamamen dijitalleştiren ve zeka teknolojisiyle donatılmıştır; bu da üstün performans sağlar, kullanımı basitleştirir ve üretim verimliliğini büyük ölçüde artırır.

BAŞVURU

Gıda endüstrisi, kimya endüstrisi, ilaç endüstrisi, sıvı ve pasta maddeleri, pump ile taşınan veya doldurulan ürünlerde (reçel, çikolata, sütlaç veya sos gibi) metal yabancı madde tespiti uygulamalarında kullanılır.

Ürün Özellikleri:

1. Metal ayırma sistemi, pompalı sıvı veya pasta ürünlerinden manyetik veya manyetik olmayan metal katkısızları (demir, çelik, alüminyum vb.) kaldırabilir.

2. Metali tespit ettikten sonra, kontamine olan malzeme kapaklı atık kutusuna çıkarılır; bu.arc kapak çıkarma cihazı, yapışkan maddeler için özel olarak tasarlanmıştır.

3. Metal ayırıcı seçme birleşimi, masaya veya duvara monte edilmek üzere stainless çelik çerçevede kullanılır. Gerektiğinde, hareketli ve ayarlanabilir bir destekle de kurulabilir.

4. Hızlı bağlayıcıyı kullanarak, var olan bir boru sistemine kolayca entegre edilebilir.

5. Yüksek dayanıklılıkta stainless çelik malzeme, temizlemesi kolaydır.

6. Kendi öğrenme fonksiyonuyla donatılmıştır, maksimum 100 farklı ürün depolama fonksiyonu vardır.

7. Çeşitli kalibreler seçilebilir, en yüksek duyarlılık 0.5mm çapındaki topu tespit edebilir

Belirti parametreleri

| Ürün | çapraz | 40mm | 50mm | 60mm | 80mm |

| hassasiyet | Fe | 0.8mm | 1.0mm | 1.2mm | 1.5mm |

| Non-fe | 1.2mm | 1.5mm | 2.0mm | 2.5mm | |

| Sus | 1.5mm | 2.0mm | 2.2mm | 2.5mm |

Güç Kaynağı: Tek faz AC220V 50/60Hz

Uyarı modu: Sesli ve görsel uyarı

Özel not: Yukarıdaki tespit duyarlılığı, laboratuvarda elde edilen parametre değeri olup, tespit edilen ürünlerin özellikleri, işletim ortamı ve özelliklerine (örneğin manyetik섭섭 interference, akış hızı, sıcaklık vs.) bağlı olarak gerçek tespit duyarlılığı farklı olacaktır ve gerçek tespit duyarlılığına dayanmalıdır.